A warm welcome!

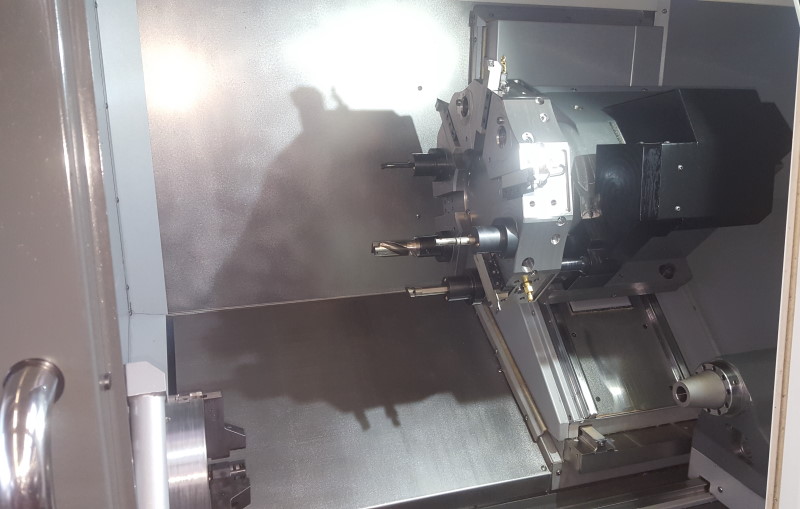

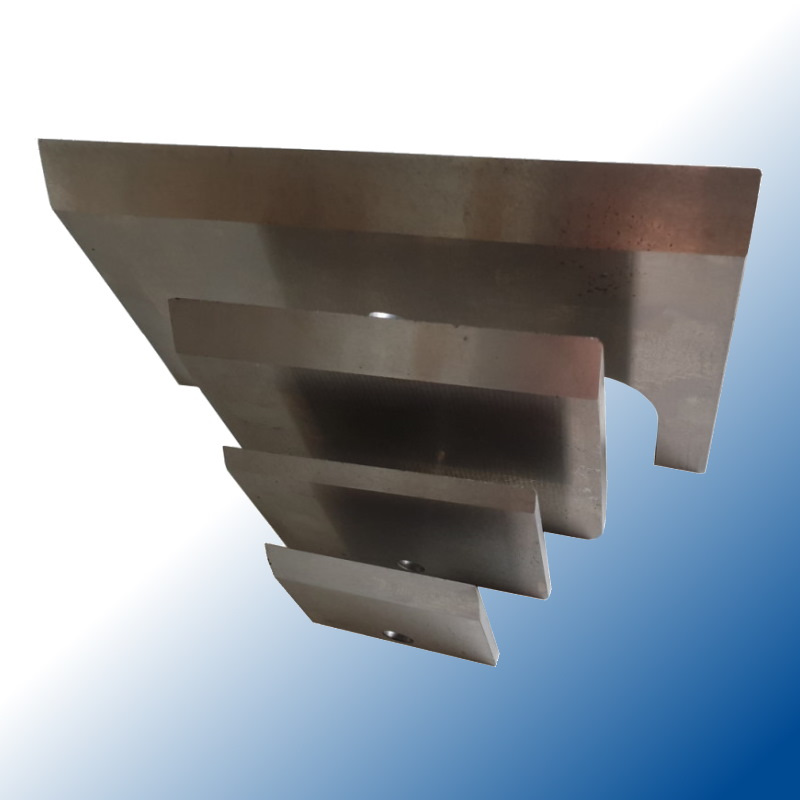

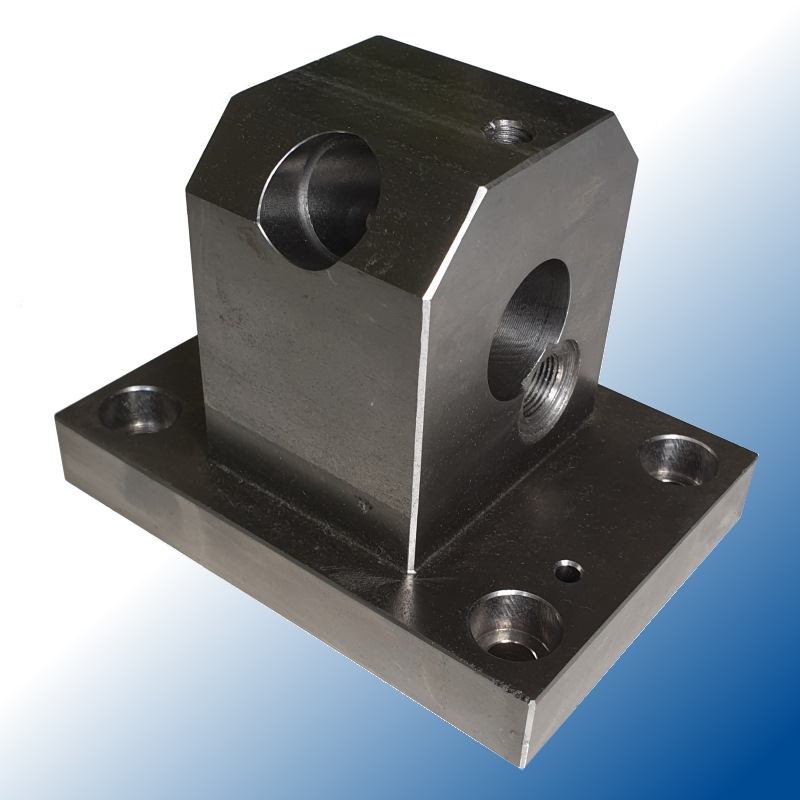

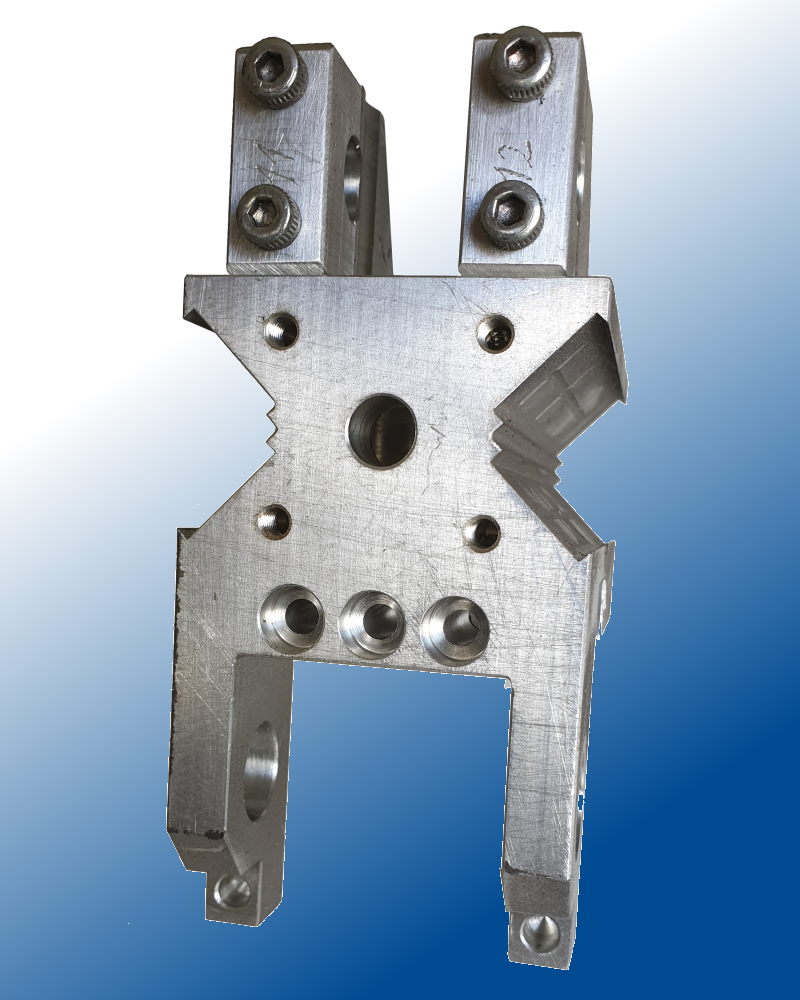

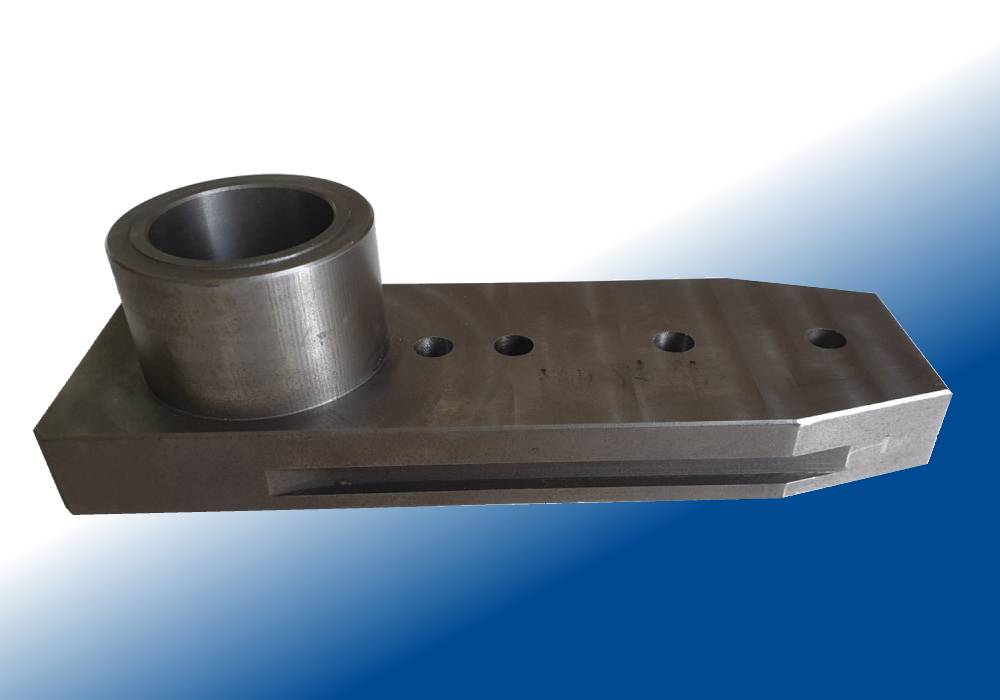

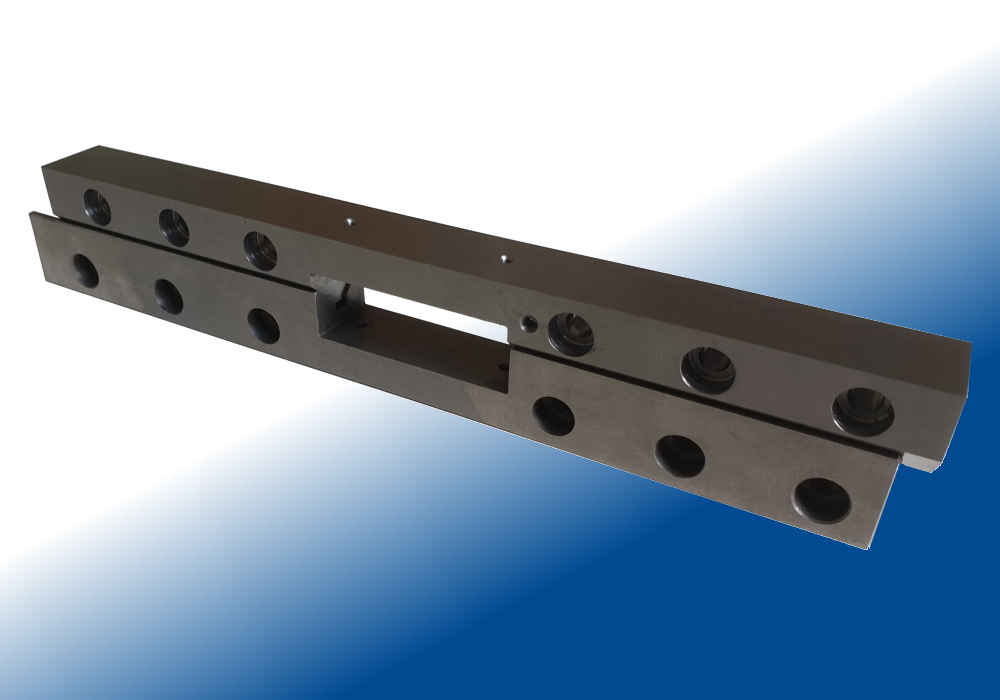

Milling, turning, surface grinding, welding, also in combination as an assembly

High-Tech meets craft.

Hardly any other craft is more true than precision engineering, which has advanced in seven-league boots since the founding of the company Martin Möschlin Feinwerktechnik GmbH (formerly Peter Wolf) 20 years ago.

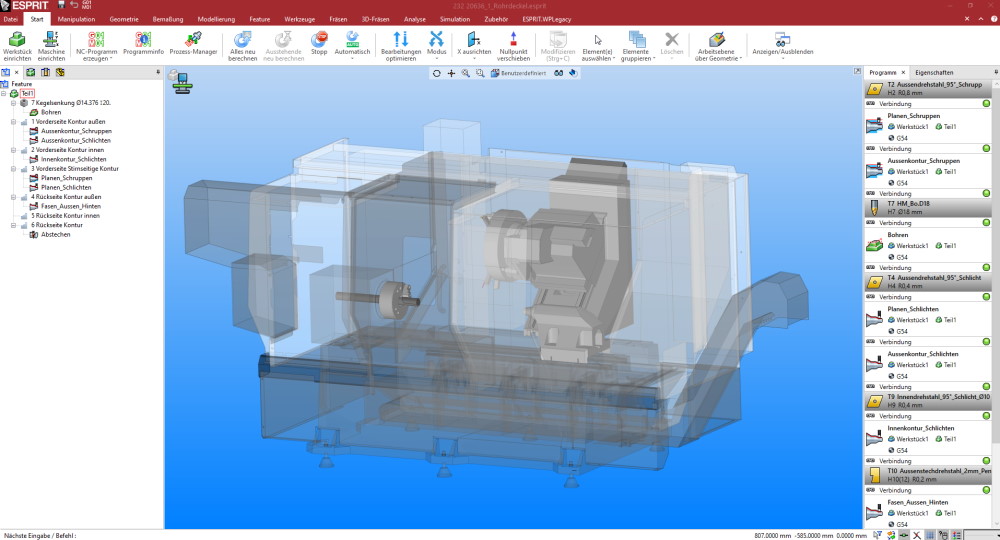

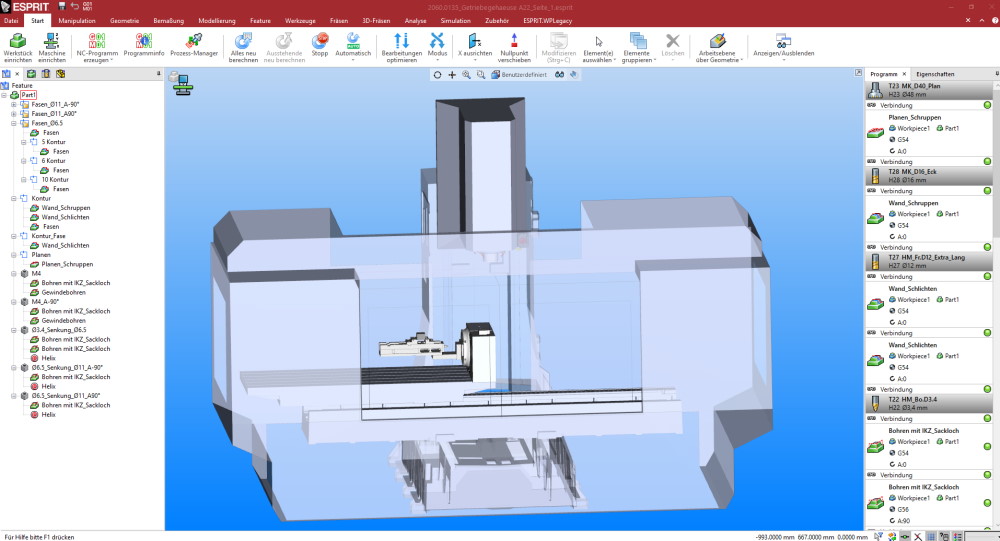

Today we mill, turn and grind by CNC to the thousandth of a millimeter, and we know no tolerance for quality. We program our machines with the latest programming system from Esprit CAM and load the programs directly via network cabling to the machines for processing the blanks and parts that our customers have entrusted us with.

Since the parts are mostly small, transport routes are not important. And that brings many advantages: As specialists, we have equipment and know-how that you do not need to acquire - because we are there, always up to date.

Keyword: Outsourcing.

A large order requires more capacity immediately - we are there. Or you are looking for the solution to a tricky problem in your production process, then we advise and develop the solution for you.

And if you have the impression that we are a service provider, then you are right with us.

High-tech meets craftsmanship - and that in full service, Europe-wide.

Your Martin Möschlin

Owner and managing director

| Editing | Size | Materials |

|---|---|---|

| Kaltenbach saws | Bar machining up to Ø 200 mm | Steel, stainless steel, Non-ferrous metals, cast iron, light metals, Plastics, Duplex steels and wood |

| CNC milling | Machining centers up to X 2134 mm, Y 813 mm, Z 762 mm |

dito |

| conventional turning | Chucking components up to Ø 250 mm | dito |

| CNC turning | Chucking components up to Ø 400 mm | dito |

| NC flat grinding | Flat grinding up to 400 x 600 / 300 x 800 mm |

Steel, stainless steel, Non-ferrous metals, cast iron, Light Metals |

| Editing | |

|---|---|

| Hardening and annealing | as compact solution |

| Surface finishing | as compact solution |

| Editing | |

|---|---|

| Welding | MIG / MAG |

| HAAS VF-7/40 CNC Machining center |

|

|---|---|

| Working area | X 2134 mm, Y 813 mm, Z 762 mm |

| Tool changer | 30 Tools |

| Dialogue control | Haas |

| Speed | n/max. 8.000 min -1 |

| HAAS VF-3SS CNC machining center |

|

|---|---|

| Working area | X 1016 mm, Y 508 mm, Z 450 mm |

| Tool changer | 30 Tools |

| Dialogue control | Haas |

| Speed | n/max. 12.000 min -1 |

| MT-CUT CNC- Machining center |

|

|---|---|

| Worling area | X 1100 mm, Y 610 mm, Z 610 mm |

| Tool changer | 30 Tools |

| Dialogue control | Heidenhain ITNC 530 |

| Speed | n/max. 10.000 min -1 |

| HAAS ST-30Y CNC-Drehmaschine with Y-Axis | |

|---|---|

| Working area | max. 457 x 584 mm |

| Bar diameter | 76 mm |

| Tool changer | hybrid Revolver with 12 station C axis |

| Dialogue control | Haas |

| Speed | n/max. 3.400 min -1 |

| Flat grinding machine Elb-Juwel 024 SPS-NK | |

|---|---|

| Fast stroke precision grinding machine (toothed belt drive) | |

| Working area | X 600 mm, Y 300 mm, Z 400 mm |

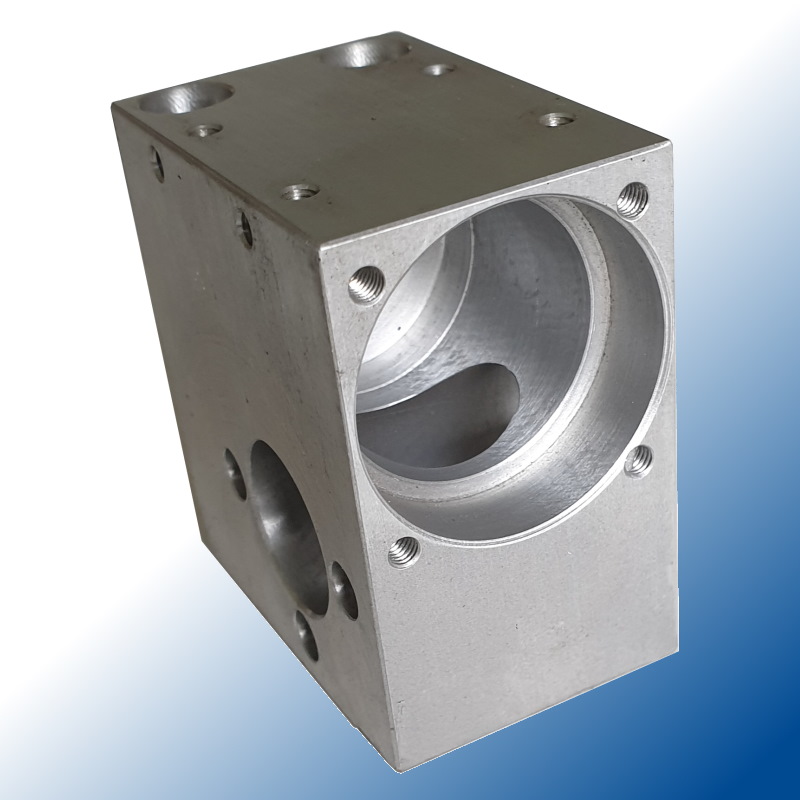

Oil pump housing material GG25

Solid Turn (Drehen)

Direct import interfaces for:

FX feature takeover from:

Inventor, Solid Edge SolidWorks

Fräsen 2.5 D und 3D und 3 Achsen Simultan

Geometry modeling, Parasolid solid and NURBS surface modeling, Adaptive feature recognition, Tool and intersection value database, Universal post-processor output, Volume-based simulation and verification, VBA Visual Basic for

Applications and ESPRIT API

General Manager

and Sales

martin.moeschlin[at]moeschlin-

feinwerktechnik.de

Administration

katja.weissenberger[at]moeschlin-

feinwerktechnik.de

Accounting and bookkeeping

gabi.moeschlin[at]moeschlin-

feinwerktechnik.de

In der Teichmatt 3

79689 Maulburg

Germany

+49 7622-61808

Office hours

Montag - Donnerstag

08.00 Uhr bis 12.00 Uhr

+49 7622-61785

info[at]moeschlin-

feinwerktechnik.de